Nustras Homologaciones

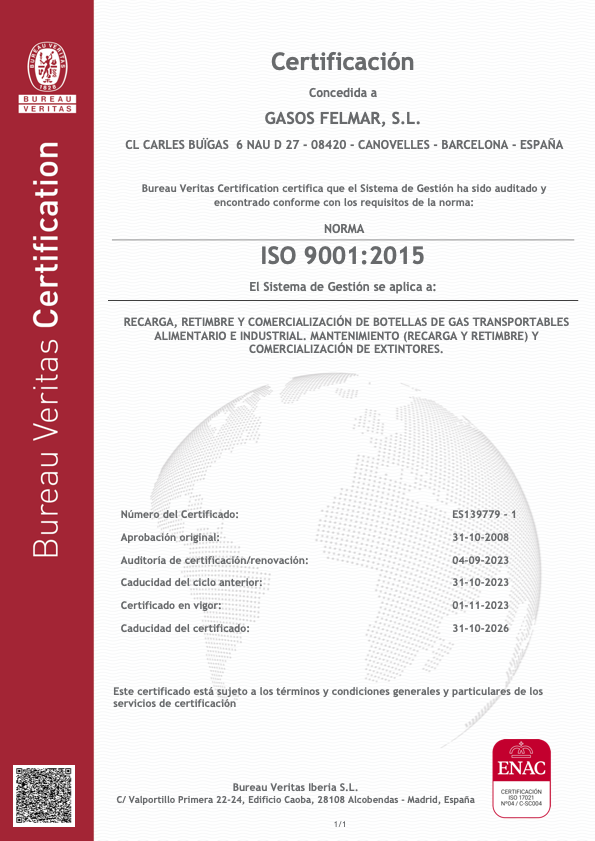

ISO 9001

EN ISO 9001 por la empresa certificadora Bureau Veritas

PLAN DE PREVENCIÓN LABORAL

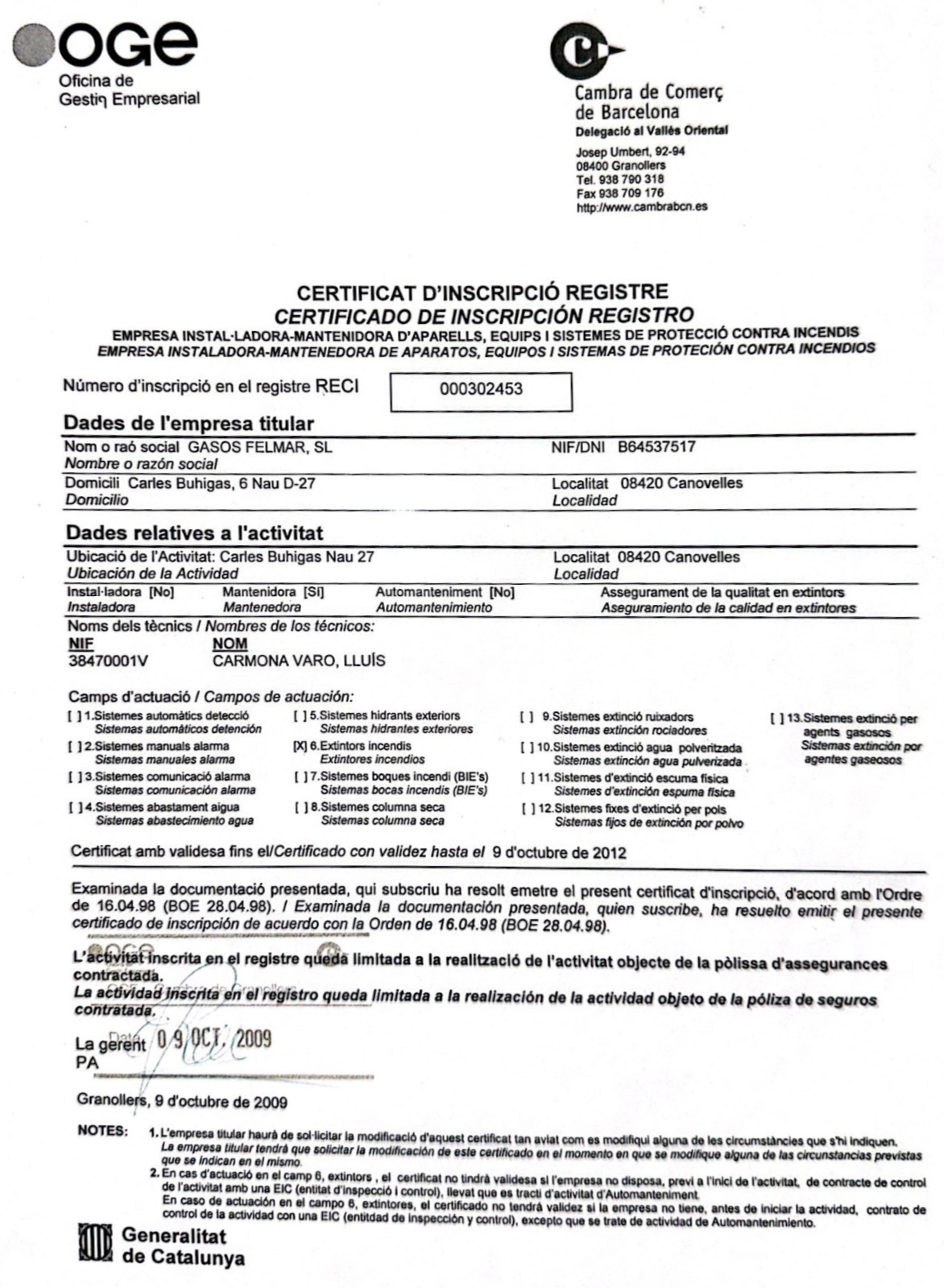

CERTIFICADO DE EMPRESA

Instaladora-Mantenedora de Aparatos, Equipos y Sistemas de Protección contra Incendios - RECI

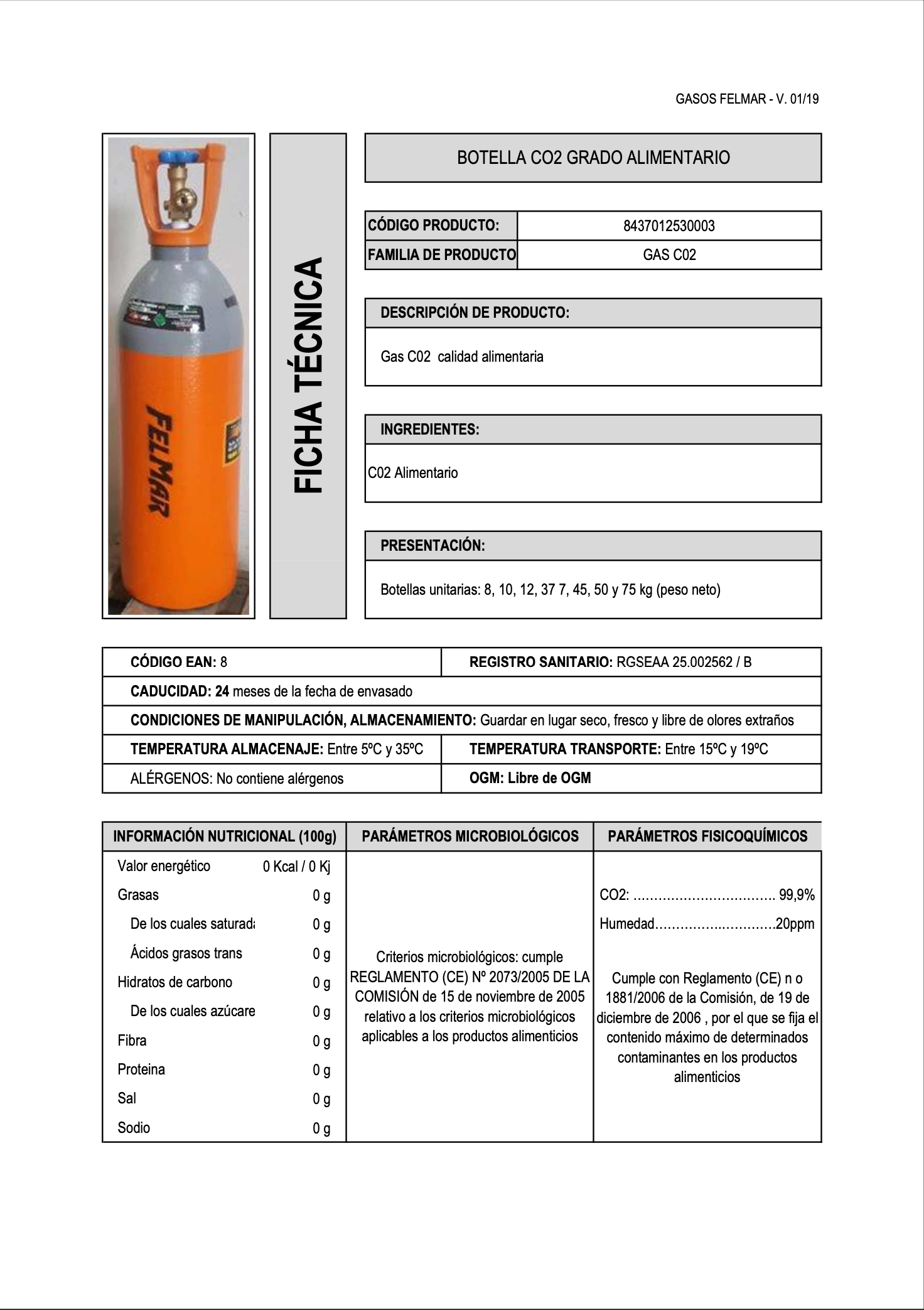

Ficha Técnica Botella CO2

FICHA DE Técnica RAL CO2 ALIMENTARIO

Ficha de Seguridad Nitrógeno

Ficha de Seguridad CO2

FICHA técnica MIX2

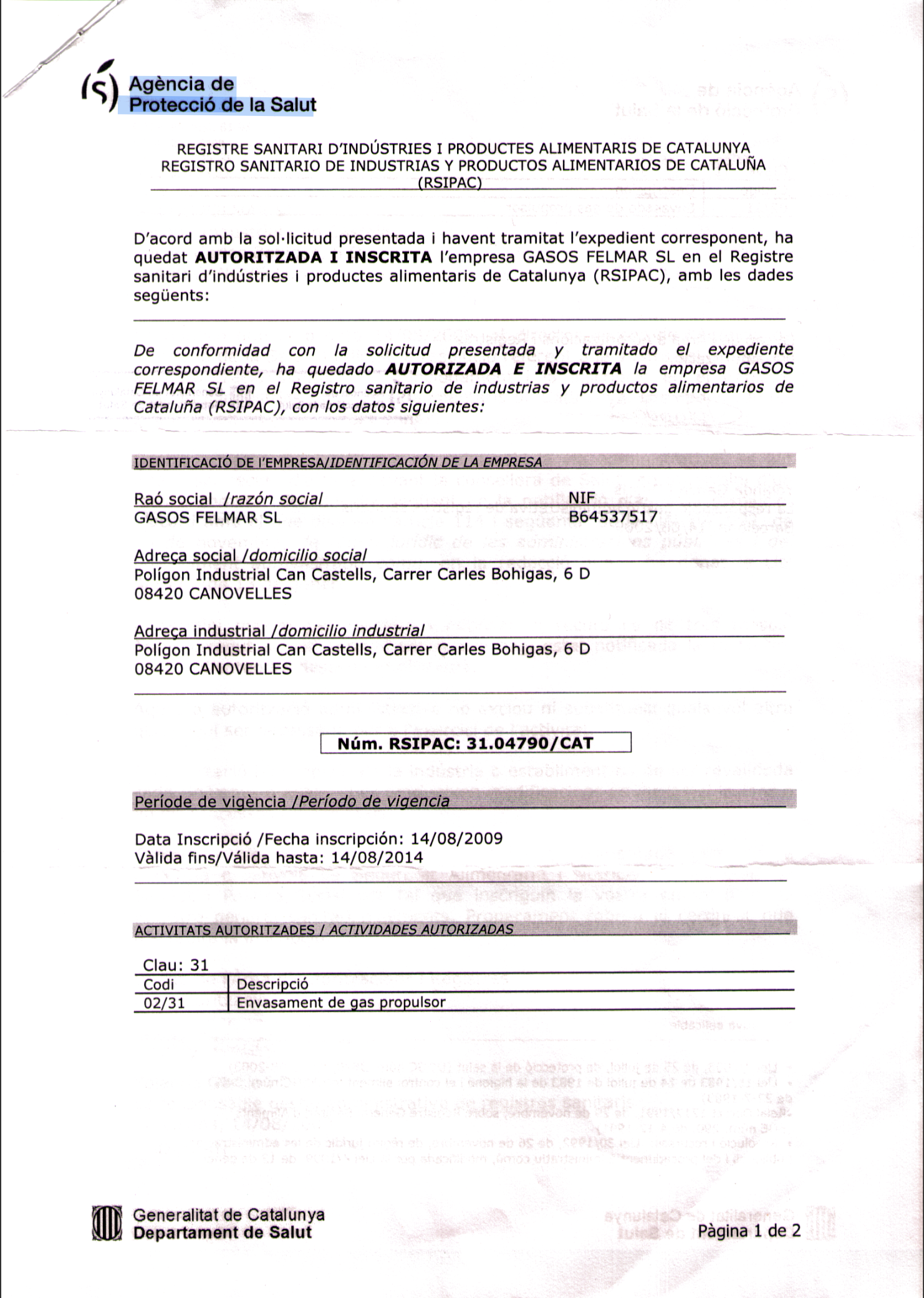

Agència de Protecció de la Salut

Certificado de Registro Sanitario Catalunya

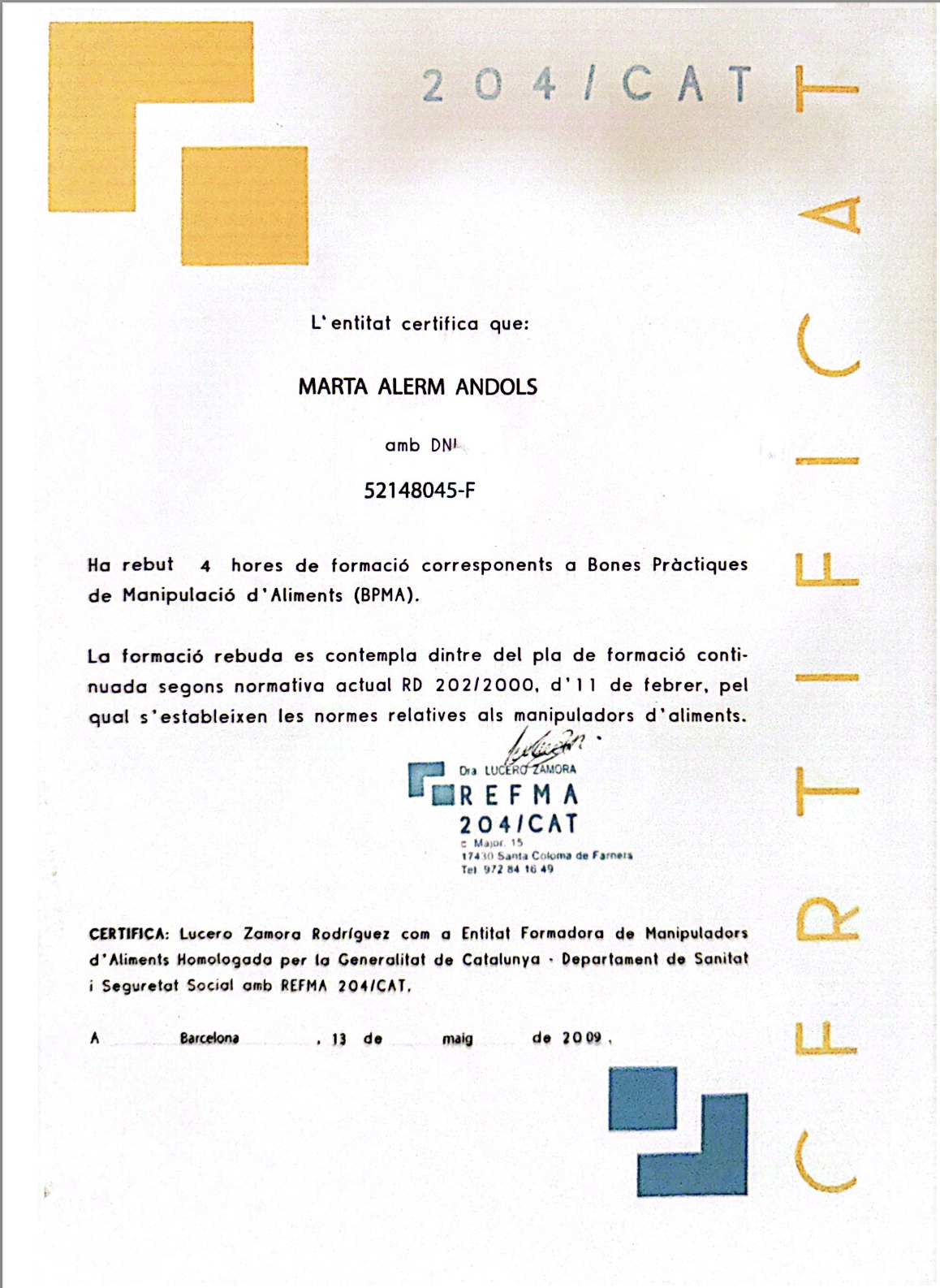

REFMA

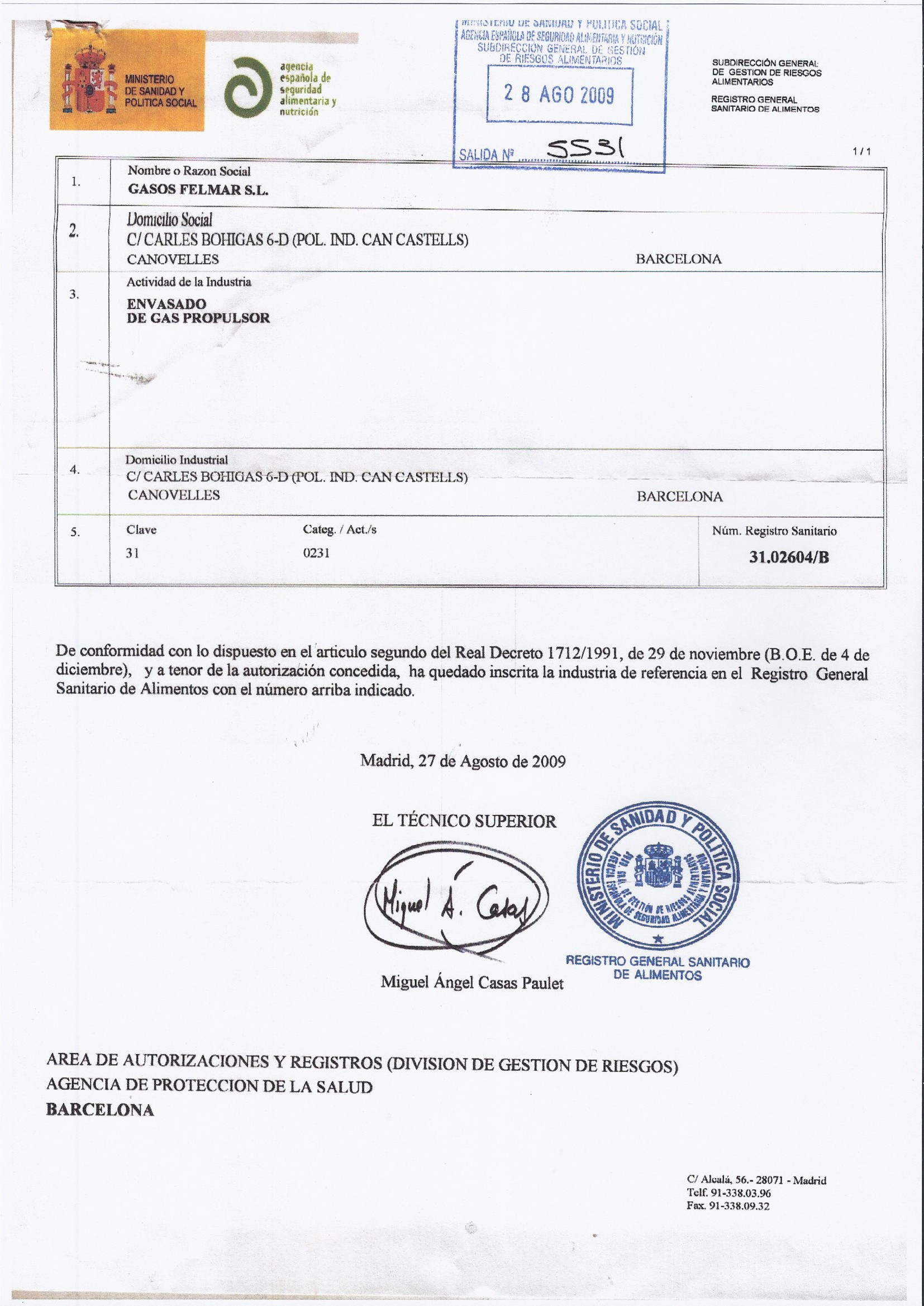

Registro Sanitario

CERTIFICADO FORMACIÓN

CERTIFICADO FORMACIÓN

- CALIDAD & SEGURIDAD

Fabrik’s prominence in tubular products for the Oil & Gas (O&G) and other sectors is no accident. Our legacy includes the API-standard Fabrik Buttress Thread. Through our dedicated Research and Technology teams, we’ve established ourselves as an innovative ally for our tubular customers, constantly devising novel products and solutions to drive both our clients and the entire industry forward.

The Research and Technology Center collaborates closely with three other Fabrik research facilities. Furthermore, the headquarters of Fabrik Tubular Products in Houston hosts an exceptional product development team dedicated to providing continuous advancements in tubular innovations for the industry.

- Research & Technology Center

Fabrik’s Product Technology Section empowers engineers and professionals with extensive, cutting-edge resources. This includes advanced testing, intricate modeling, thorough failure analysis, and more. These tools are harnessed to craft the next wave of steel innovations across various applications. Within these laboratories and facilities, the future of steel takes shape.

Mechanical Testing Facilities

At our Mechanical Testing facilities, we leverage automated equipment for conducting essential tests such as tensile and hardness measurements. These tests play a pivotal role in establishing the mechanical attributes of materials, bolstering product development and aiding customer projects. Our array of testing frames spans from 5 to 220 kip, encompassing both tensile testing and stress- or strain-controlled fatigue testing.

Electrical Steels Laboratory

The Electrical Steels Laboratory at Fabrik encompasses a range of processing and testing amenities. These are geared towards assessing cold-rolled magnetic lamination steels, which find application in producing motors, transformers, ballasts, and various electrical apparatuses. Within our laboratory, you’ll find QDA furnaces, AC and DC magnetic testers, and an interlaminar resistance tester—critical tools for our comprehensive evaluation processes.

Cold-Rolling

Laboratory

Within our Cold-Rolling Laboratory, you’ll find a Bliss four-high single-stand cold reduction mill. This mill can process strips up to 12 inches wide, achieving up to 500 fpm speeds. It’s meticulously equipped with instrumentation to capture all pertinent engineering data tied to the cold-rolling process. The facility employs a range of work rolls, optimizing rolling operations throughout Fabrik. Furthermore, it serves as a platform for refining techniques for new sheet and tin-mill products while facilitating the assessment of various cold-rolling oils.